Sheathe your cables!

As is the case with a lot of my blog posts, this one was inspired by some work I had to do for my Senior Design Project. I’ve been making wiring harnesses for running our engine for quite a while now, and while they looked good, they didn’t look very professional or durable.

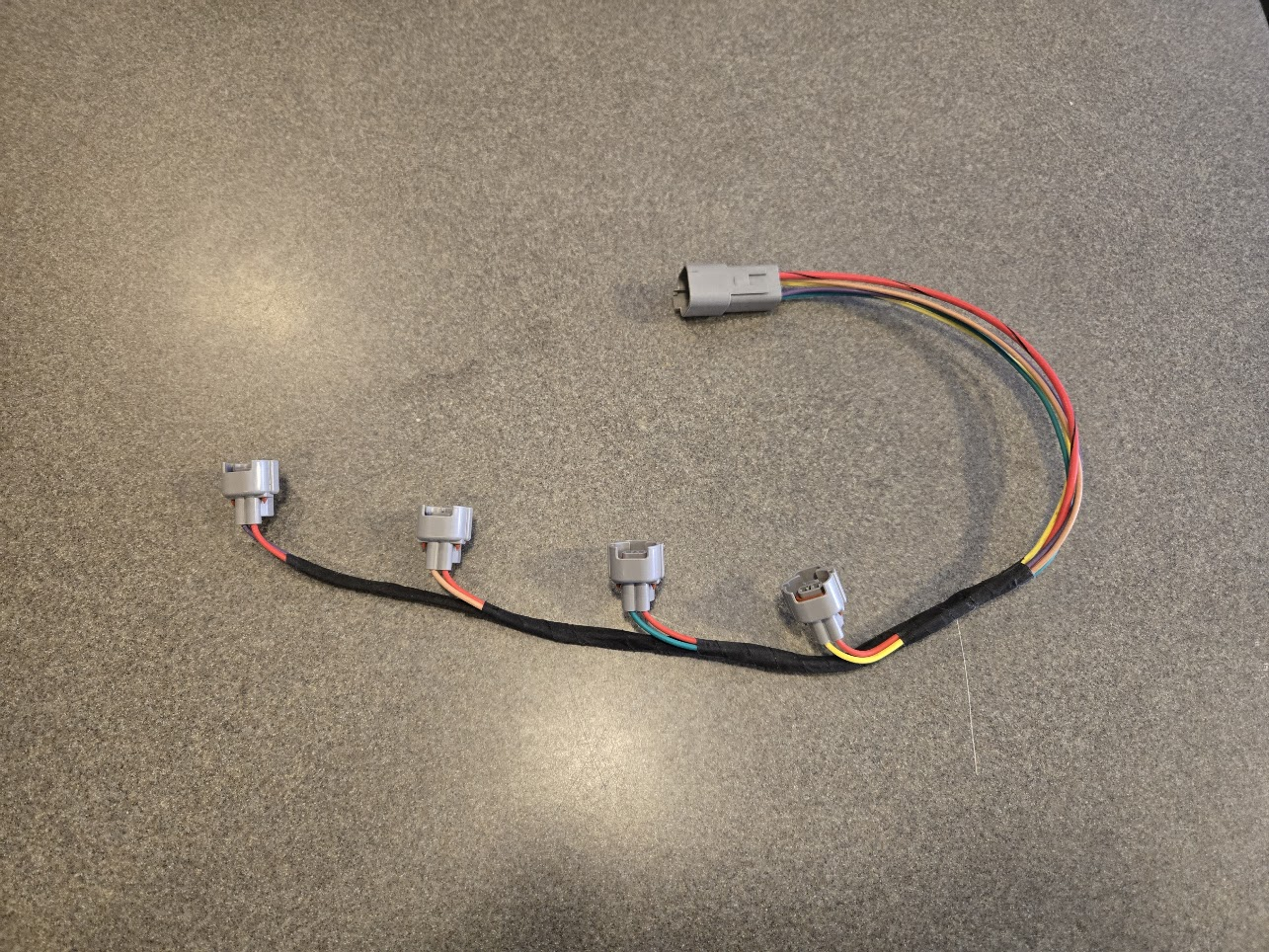

Looks good, but not great

The wiring harness was sitting in the back of my mind, and I came across a YouTube video of someone doing essentially what I’m doing for this project: converting an older engine to modern “standalone” engine management. In the video, he creates his own wiring harness, and it finally clicked what I was missing: wire sheathing!

So, I set off to M5 to give it a try on one of the parts of my wiring harness. We have wire sheathing on the bottom shelf near our heat shrink, on spools. It took a bit of depinning and some effort to ensure that all of the wires were cleanly fed through, but eventually I had some fully sheathed and protected wiring harnesses.

Much better!

Ultimately, as these wires are going to be in a harsh environment, the sheathing not only helps it to look much better, it also adds some level of protection against abrasion that these wires would greatly benefit from. I recommend anyone working on a project with exposed wiring consider adding a sheath for the protection, easier wire management and the clean look!